Maximizing Asset Uptime with Predictive Maintenance

Predictive maintenance leverages historical equipment data, real-time sensor readings, and predictive analytics to forecast potential equipment failures with a high degree of accuracy. By analyzing patterns and trends in equipment performance, predictive maintenance algorithms can identify early warning signs of impending failures, such as abnormal vibration levels, temperature fluctuations, or changes in energy consumption. Maintenance managers can then prioritize maintenance activities based on the severity and urgency of the predicted issues, optimizing resource allocation and minimizing downtime.

By implementing predictive maintenance strategies enabled by Next-Gen MES platforms, manufacturers can achieve significant cost savings by reducing unplanned downtime, minimizing maintenance costs, and extending the lifespan of critical assets. Additionally, predictive maintenance helps manufacturers transition from reactive, time-based maintenance practices to proactive, condition-based maintenance strategies, enabling them to maximize asset uptime and enhance overall operational efficiency. With real-time visibility into equipment health and performance, maintenance teams can make data-driven decisions to optimize maintenance schedules, improve asset reliability, and ultimately drive greater productivity across the manufacturing environment.

Optimizing Maintenance Operations with Advanced Analytics

One of the key advantages of incorporating advanced analytics into maintenance operations is the ability to move beyond traditional reactive maintenance approaches and adopt more proactive and predictive strategies. By analyzing historical maintenance data and equipment performance metrics, advanced analytics algorithms can identify patterns, trends, and anomalies that signal potential equipment failures or performance degradation. Armed with this predictive intelligence, maintenance teams can preemptively address issues before they escalate into costly downtime events, thereby maximizing asset uptime and productivity.

Moreover, advanced analytics enables maintenance managers to optimize resource allocation and scheduling by identifying areas of inefficiency or underutilization within the maintenance workflow. By analyzing maintenance data in real time and identifying opportunities for improvement, manufacturers can allocate resources more effectively, minimize idle time, and ensure that maintenance activities are aligned with production schedules. Additionally, advanced analytics can provide insights into the root causes of recurring maintenance issues, allowing manufacturers to implement targeted interventions and corrective actions to address underlying problems and prevent future occurrences

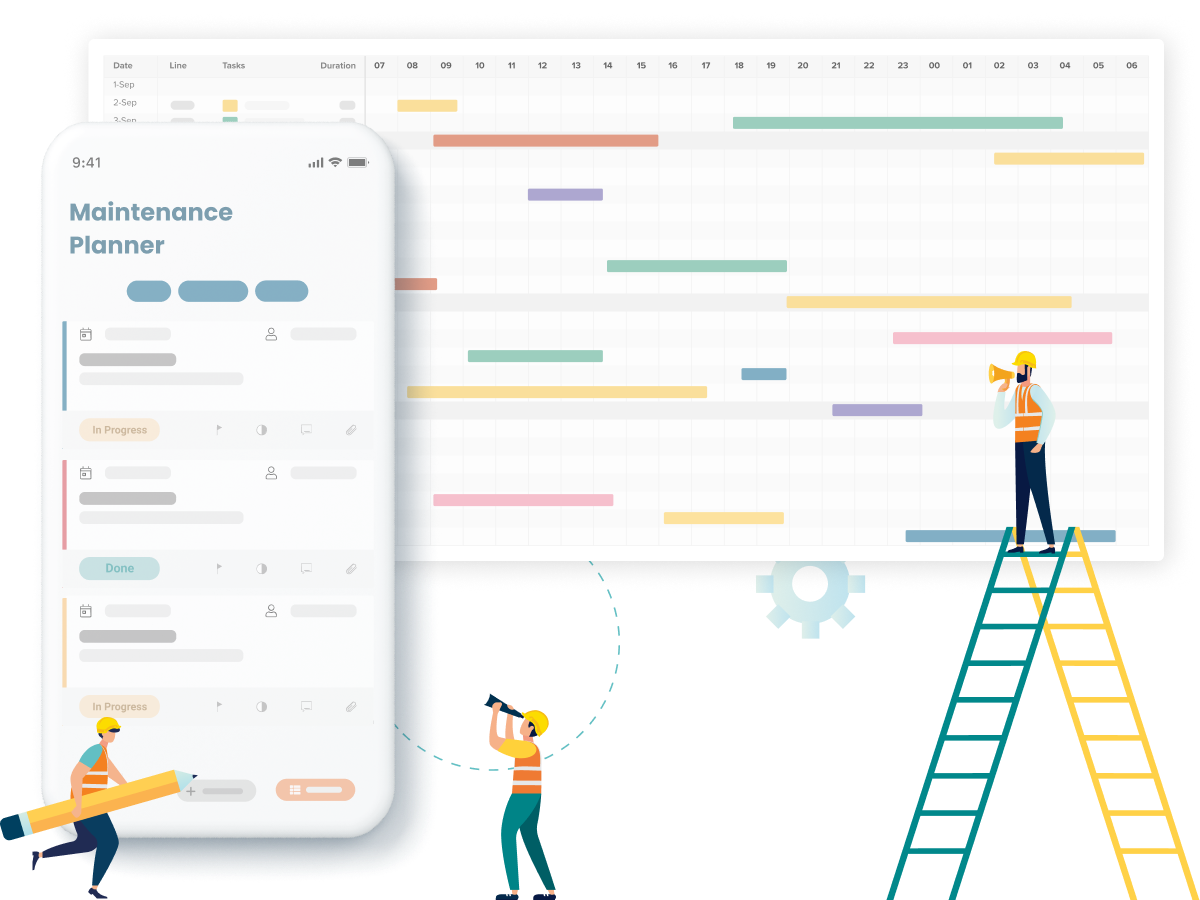

Plan maintenance anytime quickly

Maximizing Asset Performance through Predictive Maintenance

Predictive maintenance (PdM) is revolutionizing asset management in manufacturing by leveraging data analytics and machine learning algorithms to forecast equipment failures and optimize maintenance activities. By continuously monitoring equipment health and performance metrics, predictive maintenance systems can detect early signs of potential failures, enabling maintenance teams to intervene proactively and prevent unplanned downtime. This proactive approach not only minimizes disruptions to production but also extends the lifespan of critical assets, reducing maintenance costs and enhancing overall operational efficiency.

One of the key components of predictive maintenance is condition monitoring, which involves the real-time tracking of equipment parameters such as temperature, vibration, and lubrication levels. By collecting and analyzing this data, predictive maintenance systems can identify deviations from normal operating conditions and generate predictive alerts when equipment performance is trending towards failure. These early warnings empower maintenance teams to take preemptive action, whether it involves scheduling preventive maintenance tasks, ordering replacement parts, or adjusting operational parameters to mitigate risks.

Furthermore, predictive maintenance facilitates a shift from calendar-based maintenance schedules to condition-based maintenance strategies, where maintenance activities are triggered by actual asset condition rather than predetermined intervals. This dynamic approach optimizes maintenance resources by focusing efforts on assets that require attention based on their actual health and performance status. By aligning maintenance activities with asset condition and usage patterns, manufacturers can minimize unnecessary downtime, reduce maintenance costs, and maximize asset availability and reliability..

Implementing a Next-Gen MES Platform for Enhanced Asset Maintenance

Modern manufacturing enterprises are increasingly turning to next-generation Manufacturing Execution System (MES) platforms to streamline asset maintenance operations and drive operational excellence. These advanced MES solutions integrate seamlessly with predictive maintenance systems, enabling manufacturers to leverage real-time equipment data and analytics to optimize asset performance and reliability. By consolidating maintenance workflows, asset data, and analytics capabilities into a unified platform, next-gen MES solutions provide maintenance managers with comprehensive visibility and control over their asset maintenance processes.

One of the key features of next-gen MES platforms is their ability to support condition-based maintenance strategies by leveraging predictive analytics and machine learning algorithms. By analyzing historical equipment data and performance trends, these platforms can generate predictive maintenance insights that enable maintenance teams to anticipate equipment failures and proactively address maintenance issues before they escalate. Additionally, next-gen MES solutions empower maintenance managers to prioritize maintenance tasks based on criticality, asset health, and production schedules, ensuring that resources are allocated efficiently to minimize downtime and maximize asset uptime.

Furthermore, next-gen MES platforms offer advanced reporting and analytics capabilities that enable maintenance managers to gain actionable insights into asset performance, maintenance activities, and overall equipment effectiveness (OEE). By leveraging real-time dashboards, KPIs, and performance metrics, maintenance teams can track key maintenance indicators, identify performance bottlenecks, and make data-driven decisions to optimize asset maintenance processes. Additionally, these platforms facilitate continuous improvement initiatives by enabling maintenance managers to analyze historical maintenance data, identify root causes of equipment failures, and implement preventive measures to enhance asset reliability and availability over time.

Maximizing Efficiency and Reliability Through Integrated Asset Management

Integrated asset management solutions enable manufacturers to centralize all asset-related information and activities within a single platform, eliminating the need for disparate systems and manual data entry. This centralized approach allows maintenance teams to access real-time asset data, maintenance history, and performance analytics from anywhere, enabling them to make informed decisions and take proactive maintenance actions. Additionally, integrated asset management solutions facilitate seamless collaboration between maintenance, production, and engineering teams, enabling cross-functional teams to work together more effectively to optimize asset performance and reliability.

Furthermore, integrated asset management solutions leverage advanced technologies such as IoT sensors, predictive analytics, and machine learning to monitor asset health in real-time and predict potential failures before they occur. By continuously monitoring asset performance metrics and analyzing historical data, these solutions can identify early warning signs of equipment degradation or impending failures, allowing maintenance teams to intervene proactively and prevent costly downtime. Additionally, integrated asset management solutions enable manufacturers to implement condition-based and predictive maintenance strategies, optimizing maintenance schedules and resource allocation to maximize asset uptime and minimize maintenance costs.

Some Benefits of MES

Next-gen MES platforms can help improve asset maintenance planning and increase equipment uptime. By providing real-time data, advanced analytics, and integrated workflows, next-gen MES platforms can help optimize operations across the enterprise.

- Real-time data: By providing real-time information on critical components such as fluid levels or temperature readings from machines in operation or machinery that is being serviced by field service technicians (i.e., oil changes), the platform enables better decision-making around parts replacement schedules and maintenance tasks based on actual operating conditions rather than estimates or historical averages.

- Advanced analytics: Advanced analytics are used in conjunction with machine telemetry to support predictive maintenance by identifying potential problems before they occur so preventive measures can be taken before there's an issue - helping reduce unplanned downtime due to unscheduled shutdowns caused by mechanical failure or other issues related to wear/tear over time (e.g., excess vibration).

- Integrated workflows: An integrated workflow allows users access all relevant information from one central location without having multiple applications open simultaneously across different screens which makes it easier for teams across departments (elevator installers/repairers vs elevator technicians) to collaborate effectively.

Maximizing Efficiency and Reliability Through Integrated Asset Management

The ability to optimize operations and improve maintenance planning is a huge benefit of a next-generation MES platform. When you have the right data, it's easy to see what's happening with your equipment--and make changes accordingly.

With a system that's designed specifically around asset management, you'll get elevated visibility into the health of your machines, as well as real-time data from sensors on each piece of equipment in your facility or fleet. You can also use machine learning algorithms to identify patterns in performance data over time so that you can predict when maintenance should occur before it becomes an issue (or even avoid costly repairs).

Advanced analytics also help businesses better understand their assets' usage patterns by correlating production metrics with maintenance activities across multiple facilities or sites--and then allowing them to make informed decisions based on those insights. For example: If we see our machine X has been running at its highest capacity for this period of time without any issues but now needs repairs due diligence must be done before investing further capital into this particular piece of equipment.

Share maintenance planning with your team

Conclusion

MES platforms are essential for optimizing a manufacturing operation. They provide real-time data, advanced analytics and integrated workflows that can help you improve asset maintenance planning and increase equipment uptime. By leveraging the benefits of next-gen MES platforms, organizations can gain greater visibility into their operations while reducing costs by making better decisions faster than ever before.